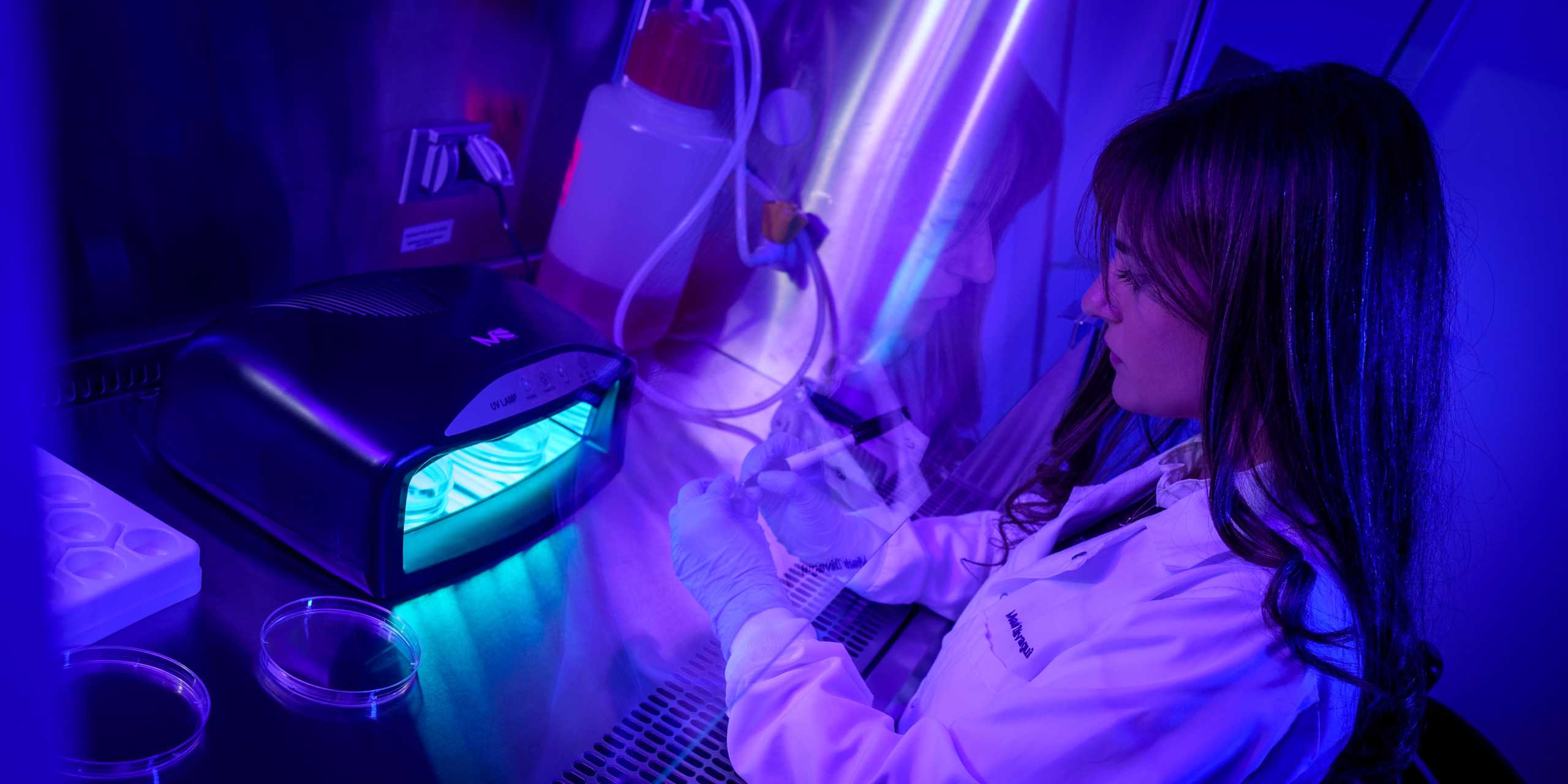

In the fast-paced world of manufacturing and technology, efficiency and precision are key factors that drive success. UV Curing Systems have emerged as a game-changer in various industries, offering a reliable and efficient method for curing coatings, adhesives, and inks. This cutting-edge technology harnesses the power of ultraviolet (UV) light to create instant cures, revolutionizing production processes across the board.

Understanding UV Curing Systems: UV curing involves the use of ultraviolet light to initiate a chemical reaction that instantly cures or dries coatings, inks, adhesives, and other materials. UV curing systems consist of a UV light source, a reflector, and a conveyor system to ensure uniform curing. The process is swift, efficient, and environmentally friendly, making it a preferred choice for various applications.

Key Advantages of UV Curing Systems:

- Speed and Efficiency: UV curing is exceptionally fast compared to traditional curing methods. The ability to cure materials in seconds or milliseconds accelerates production cycles, leading to increased throughput and reduced manufacturing times.

- Energy Efficiency: UV curing systems are energy-efficient, consuming less power compared to other curing technologies. The targeted use of UV light minimizes heat generation, resulting in lower energy consumption and reduced environmental impact.

- Improved Quality: The instantaneous curing provided by UV systems enhances the quality of finished products. The absence of solvent evaporation and the uniform curing process contribute to better adhesion, scratch resistance, and overall durability of coatings.

- Reduced VOC Emissions: Unlike solvent-based curing methods, UV curing systems emit minimal volatile organic compounds (VOCs). This is a significant advantage in terms of environmental sustainability and compliance with regulatory standards.

- Versatility: UV curing is a versatile technology applicable to various substrates, including plastics, metals, glass, and composites. This adaptability makes it a go-to solution for industries ranging from automotive and electronics to packaging and healthcare.

Applications Across Industries:

- Printing and Packaging: UV curing systems play a crucial role in the printing and packaging industry, where rapid curing times and high-quality finishes are paramount. Applications include labels, flexible packaging, and cardboard boxes.

- Electronics: The electronics industry benefits from UV curing in the assembly of electronic components, ensuring reliable adhesion and encapsulation of sensitive devices.

- Automotive: In automotive manufacturing, UV curing is used for coatings on various components, including interior trims, headlights, and touchscreens. The speed of UV curing aligns with the demands of mass production in the automotive sector.

- Wood and Furniture: Wood coatings and furniture manufacturing leverage UV curing for its ability to provide a durable and aesthetically pleasing finish without compromising on production speed.

Conclusion: UV curing systems have emerged as a transformative force, reshaping manufacturing processes across diverse industries. The speed, efficiency, and environmental benefits of UV curing make it an attractive choice for businesses aiming to stay ahead in today’s competitive landscape. As technology continues to advance, we can expect further innovations in UV curing systems, unlocking new possibilities for enhanced productivity and product quality. Embracing this technology is not just a step forward; it’s a leap into the future of efficient and sustainable manufacturing.