In today’s fiercely competitive business landscape, organizations are constantly seeking ways to optimize processes, enhance quality, and reduce costs. One methodology that has emerged as a game-changer in this pursuit is Lean Six Sigma. In this blog, we will delve into the world of Lean Six Sigma, exploring its principles, methodologies, and the remarkable impact it can have on business transformation.

Chapter 1: The Essence of Lean Six Sigma

Understanding Lean Six Sigma

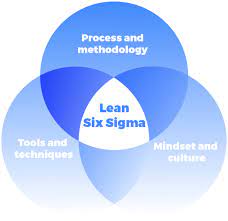

Lean Six Sigma is a powerful blend of two methodologies: Lean and Six Sigma. It combines Lean’s focus on waste reduction and process efficiency with Six Sigma’s emphasis on data-driven problem-solving and quality improvement.

Core Principles

- Customer Focus: Lean Six Sigma starts with understanding and meeting customer needs.

- Data-Driven: It relies on data and statistical analysis for decision-making.

- Continuous Improvement: A culture of ongoing process enhancement is central to Lean Six Sigma.

Chapter 2: The Lean Six Sigma Methodology

DMAIC and DMADV

- DMAIC (Define, Measure, Analyze, Improve, Control): This is the core framework for improving existing processes.

- DMADV (Define, Measure, Analyze, Design, Verify): Used for designing new processes/products.

Tools and Techniques

Lean Six Sigma employs various tools like process mapping, root cause analysis, Pareto charts, and control charts to identify, measure, and address process issues.

Chapter 3: Benefits of Lean Six Sigma

Enhanced Efficiency

Lean Six Sigma helps organizations streamline processes, reduce waste, and improve resource utilization, resulting in increased efficiency.

Improved Quality

By focusing on reducing defects and variations, Lean Six Sigma enhances product or service quality, leading to higher customer satisfaction.

Cost Reduction

The methodology identifies and eliminates unnecessary costs, contributing to significant financial savings.

Chapter 4: Lean Six Sigma Success Stories

Toyota

Toyota pioneered Lean principles in manufacturing, leading to remarkable process efficiencies and high-quality production.

General Electric

General Electric’s successful implementation of Lean Six Sigma resulted in billions of dollars in savings and process improvements.

Amazon

Amazon applies Lean Six Sigma principles in its logistics and fulfillment centers, ensuring swift and accurate deliveries.

Chapter 5: Getting Started with Lean Six Sigma

Training and Certification

Invest in Lean Six Sigma training for your team to build the necessary skills and knowledge.

Project Selection

Identify key projects that align with organizational goals and can benefit from Lean Six Sigma methodologies.

Cultivating a Lean Culture

Promote a culture of continuous improvement where employees are encouraged to identify and address process issues.