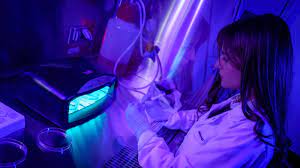

In the ever-evolving landscape of manufacturing and technology, UV curing systems have emerged as powerful tools, revolutionizing processes across various industries. From printing and coating to electronics and medical devices, the applications of UV curing are vast and impactful. In this comprehensive guide, we’ll delve into the world of UV curing systems, exploring what they are, how they work, and the diverse range of industries benefitting from their cutting-edge technology.

Understanding UV Curing Systems:

What is UV Curing?

UV curing is a process that uses ultraviolet (UV) light to initiate a chemical reaction, typically in a photosensitive material, leading to its rapid curing or hardening. UV curing systems employ high-intensity UV lamps to emit light within the UVA and UVB spectra, triggering the curing process in materials such as inks, coatings, adhesives, and more.

Components of UV Curing Systems:

- UV Lamps: High-performance UV lamps are the heart of UV curing systems. These lamps emit UV light at specific wavelengths to activate photoinitiators in the material being cured.

- Reflectors: Reflectors are strategically placed to optimize the distribution of UV light, ensuring uniform curing across the treated surface.

- Cooling Systems: UV lamps generate heat during operation, and efficient cooling systems are essential to maintain optimal operating temperatures and prolong the lifespan of the lamps.

- Control Systems: Advanced control systems regulate parameters such as intensity, duration, and temperature, providing precision and flexibility in the curing process.

How UV Curing Works:

- Photoinitiation: When UV light from the lamp strikes the photoinitiators in the material, it initiates a chemical reaction, creating reactive species.

- Polymerization: The reactive species quickly polymerize or crosslink the molecules in the material, transforming it from a liquid or gel state to a solid state.

- Instant Curing: Unlike traditional curing methods that rely on heat or evaporation, UV curing is instantaneous, allowing for faster production cycles and reduced energy consumption.

Applications Across Industries:

1. Printing Industry:

- UV curing is widely used in printing processes, including offset, flexography, and digital printing. It enables instant drying of inks and coatings on various substrates, leading to high-quality, vibrant prints.

2. Coatings and Adhesives:

- UV curing systems are employed in the application of protective coatings on surfaces and the bonding of adhesives in industries such as automotive, electronics, and furniture manufacturing.

3. Electronics:

- In the electronics industry, UV curing is utilized for encapsulation, conformal coating, and solder mask applications. It ensures efficient and precise protection of electronic components.

4. Medical Devices:

- UV curing plays a vital role in the production of medical devices, where precision and speed are critical. Applications include bonding, sealing, and coating in the manufacturing of medical equipment.

5. Wood and Furniture:

- UV curing systems enhance the efficiency of finishing processes in the wood and furniture industry. They provide durable and glossy finishes while reducing production time.

6. Automotive:

- UV curing is applied in automotive manufacturing for tasks such as clear coat curing, adhesion promotion, and interior component bonding.

Advantages of UV Curing Systems:

- Speed and Efficiency: UV curing is exceptionally fast, allowing for high-speed production lines and increased efficiency.

- Energy-Efficient: The instant curing process minimizes energy consumption compared to traditional curing methods that rely on prolonged heating.

- Enhanced Quality: UV-cured materials often exhibit superior properties, including hardness, durability, and resistance to chemicals and abrasion.

- Reduced Footprint: UV curing eliminates the need for large drying ovens, saving floor space and contributing to a more compact manufacturing environment.

- Environmentally Friendly: UV curing systems typically produce minimal volatile organic compounds (VOCs), making them environmentally friendly compared to solvent-based curing methods.

Future Trends and Innovations:

- LED UV Technology: The adoption of LED UV lamps is gaining traction for their energy efficiency, longer lifespan, and precise control over curing parameters.

- Customization and Flexibility: UV curing systems are evolving to offer greater flexibility in adapting to diverse materials and application requirements, catering to the growing demand for customization.

- Smart Integration: Integration with Industry 4.0 principles, including IoT connectivity and data analytics, is becoming more prevalent, allowing for real-time monitoring and optimization of UV curing processes.