In a world where electronic devices are becoming increasingly integral to our daily lives, the need for reliable and durable connectors is more crucial than ever. One groundbreaking solution that has emerged to meet this demand is the waterproof power connector. In this blog, we’ll explore the advantages, applications, and the technological marvel behind these connectors that are making waves in various industries.

Section 1: The Need for Waterproof Power Connectors In environments where exposure to water, moisture, and other harsh elements is inevitable, traditional power connectors may falter, leading to electrical failures and safety hazards. Waterproof power connectors address this challenge by providing a robust and secure connection that can withstand the elements. From outdoor lighting systems to marine applications, these connectors offer a reliable power solution in demanding conditions.

Section 2: Key Features of Waterproof Power Connectors

- IP-Rated Protection: Waterproof connectors are often rated using the Ingress Protection (IP) code, indicating their resistance to dust and water. The higher the IP rating, the greater the protection. These connectors are designed to meet specific IP standards, ensuring a reliable barrier against water infiltration.

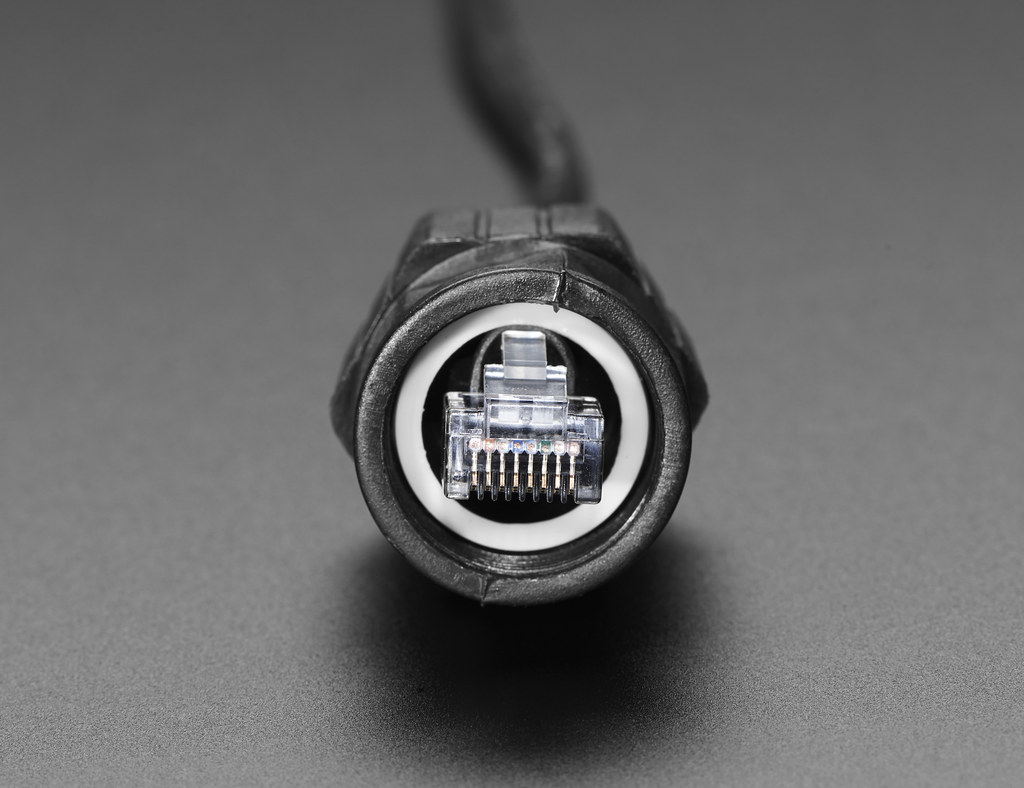

- Sealed Construction: The connectors boast a sealed construction, preventing water from entering and compromising the electrical components. This sealing mechanism is achieved through advanced engineering, including gaskets, O-rings, and other sealing materials.

- Corrosion Resistance: Many waterproof power connectors are built with corrosion-resistant materials, such as stainless steel or specialized alloys. This feature ensures longevity and reliability, especially in marine or coastal environments where exposure to saltwater is a concern.

Section 3: Applications Across Industries Waterproof power connectors find applications in a diverse range of industries, showcasing their versatility and adaptability. Some notable sectors include:

- Marine and Maritime: Used in boat and ship electrical systems, navigation equipment, and underwater lighting.

- Outdoor Lighting: Ideal for landscape lighting, street lighting, and other outdoor installations exposed to the elements.

- Automotive: Employed in electric vehicles, motorcycles, and other automotive applications where water resistance is crucial.

- Industrial Equipment: Used in machinery, sensors, and control systems in industrial settings with exposure to moisture.

Section 4: Technological Advancements The evolution of waterproof power connectors is closely tied to advancements in materials and manufacturing processes. Modern connectors often incorporate innovative features such as quick-connect mechanisms, modular designs, and enhanced shielding to meet the evolving needs of various industries.