In today’s rapidly advancing technological landscape, the demand for durable and reliable electrical connections has never been higher. Whether you’re working on an outdoor project, marine application, or simply want to safeguard your electrical connections from the elements, waterproof wiring connectors are the key to ensuring longevity and performance. In this blog, we’ll dive into the world of waterproof connectors, exploring their benefits, applications, and why they’re essential for a wide range of industries.

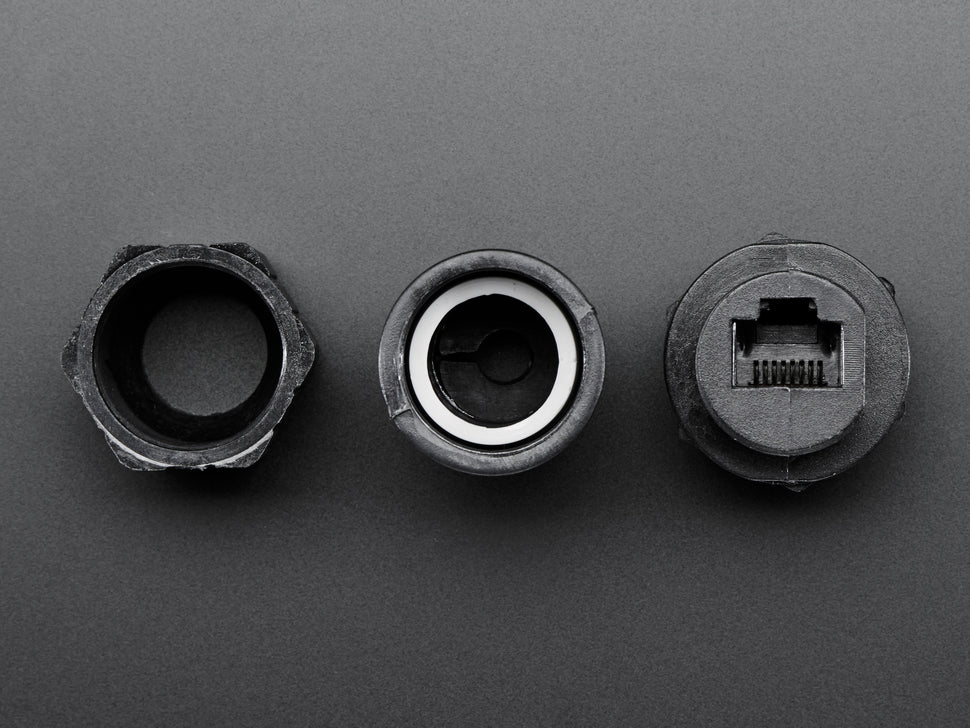

- Understanding Waterproof Connectors: Waterproof wiring connectors are designed to protect electrical connections from moisture, dust, and other environmental factors. These connectors often adhere to Ingress Protection (IP) ratings, indicating their resistance to water and solid particles. Understanding these ratings is crucial for selecting the right connector for your specific needs.

- Versatility in Applications: One of the standout features of waterproof connectors is their versatility. From outdoor lighting installations and marine electronics to automotive wiring and industrial machinery, these connectors find applications across various industries. Their ability to withstand harsh conditions makes them indispensable for projects where exposure to water is a constant concern.

- Benefits of Waterproof Connectors:

- Reliability: Waterproof connectors enhance the reliability of electrical systems by preventing corrosion and damage caused by exposure to water.

- Durability: Designed to withstand challenging environmental conditions, these connectors are built to last, ensuring a longer lifespan for your electrical connections.

- Safety: Waterproof connectors contribute to safety by reducing the risk of electrical malfunctions and potential hazards associated with moisture infiltration.

- Choosing the Right Connector for Your Needs: Selecting the appropriate waterproof connector depends on factors such as the application, environmental conditions, and the level of protection required. Consider the specific IP rating needed, the type of wiring involved, and the connector’s compatibility with your equipment. Taking these factors into account will help you make an informed decision and ensure optimal performance.

- Installation Tips and Best Practices:

- Proper Sealing: Ensure that connectors are properly sealed to prevent water ingress. Follow manufacturer guidelines for sealing methods and use appropriate sealants.

- Secure Connections: Make sure to secure connections tightly and use the correct tools for installation to maintain the integrity of the waterproofing features.

- Regular Inspections: Periodically inspect and maintain waterproof connectors to identify any signs of wear or damage. Replace connectors that show signs of deterioration to avoid potential issues.