In today’s fast-paced and interconnected world, where technology plays a pivotal role in every aspect of our lives, ensuring the reliability and durability of electronic devices is of utmost importance. One critical component that contributes significantly to the resilience of electronic systems is the humble yet powerful waterproof connector. These connectors have revolutionized industries by providing a robust solution to challenges posed by water, moisture, and harsh environmental conditions. In this blog post, we’ll dive into the depths of waterproof connectors, exploring their applications, advantages, and the technological innovations that make them indispensable.

Understanding Waterproof Connectors:

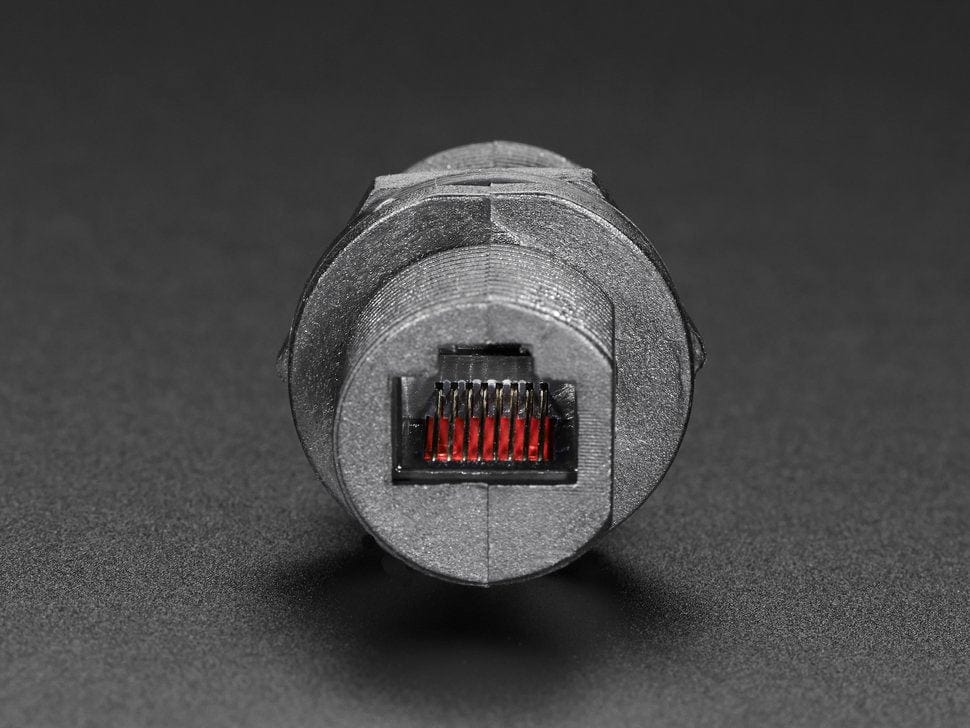

Waterproof connectors are specially designed electrical connectors that prevent the ingress of water and moisture, safeguarding electronic devices and systems from potential damage. They are engineered to maintain a secure and reliable electrical connection even in challenging environments where exposure to liquids is a constant threat. These connectors find applications in various industries, including automotive, marine, aerospace, medical, and outdoor electronics.

Applications of Waterproof Connectors:

- Marine and Offshore Industries:

- Waterproof connectors play a crucial role in marine and offshore applications, where exposure to saltwater and harsh weather conditions is inevitable. They are used in navigation systems, communication equipment, and lighting fixtures on ships and offshore platforms.

- Automotive Sector:

- In the automotive industry, waterproof connectors ensure the proper functioning of electronic components, even in the presence of moisture and contaminants. They are used in various applications, such as sensors, lighting systems, and onboard entertainment.

- Medical Devices:

- Medical devices often require waterproof connectors to maintain their functionality in sterilization processes or in environments where exposure to liquids is possible. These connectors contribute to the reliability of critical medical equipment.

- Outdoor Electronics:

- Outdoor electronic devices, such as cameras, GPS units, and wearable technology, benefit from waterproof connectors to withstand rain, humidity, and other environmental factors. This ensures the longevity and reliability of these devices during outdoor activities.

Advantages of Waterproof Connectors:

- Reliability in Harsh Environments:

- Waterproof connectors provide a reliable electrical connection even in challenging conditions, making them ideal for applications where exposure to water, moisture, and contaminants is a concern.

- Durability and Longevity:

- The rugged design of waterproof connectors enhances the durability and longevity of electronic systems by protecting them from environmental elements. This is particularly crucial in industries where equipment is subjected to extreme conditions.

- Prevention of Corrosion:

- By preventing the ingress of water and moisture, waterproof connectors help mitigate the risk of corrosion on electrical contacts, ensuring optimal performance over an extended period.

Technological Innovations:

- Sealing Technologies:

- Advanced sealing technologies, such as gaskets, o-rings, and potting materials, contribute to the effectiveness of waterproof connectors in preventing water ingress.

- Material Selection:

- The use of high-quality materials, including corrosion-resistant metals and robust polymers, enhances the overall performance and reliability of waterproof connectors.

- IP Ratings:

- Waterproof connectors are often classified with Ingress Protection (IP) ratings, indicating their resistance to dust and water. Understanding these ratings helps users choose the right connector for specific environmental conditions.